The new generation coating printing machine features an added coating printing mechanism compared to the previous model, allowing products to have characteristics such as resistance to alcohol or disinfectants.

It includes an improved screw feeding mechanism that significantly reduces pressure between ampoule. Additionally, new components like screw hot air, side-blowing hot air via spiral tracks, and chain hot air mechanisms ensure consistent drying during the ampoule printing process.

The redesigned ampoule turning mechanism guarantees adequate drying after printing, while improved screws and related supports further simplify the replacement process of specification parts, enhancing the device’s usability.

Overall, the new generation coating printing machine significantly improves printing quality and equipment stability.

Main Features

1. High speed and stability

2. Excellent printing quality and strong adhesion

3. Strong compatibility, suitable for 1-20 ml ampoule bottles

4. Low material costs, environmentally friendly and energy-saving

Technical Parameter

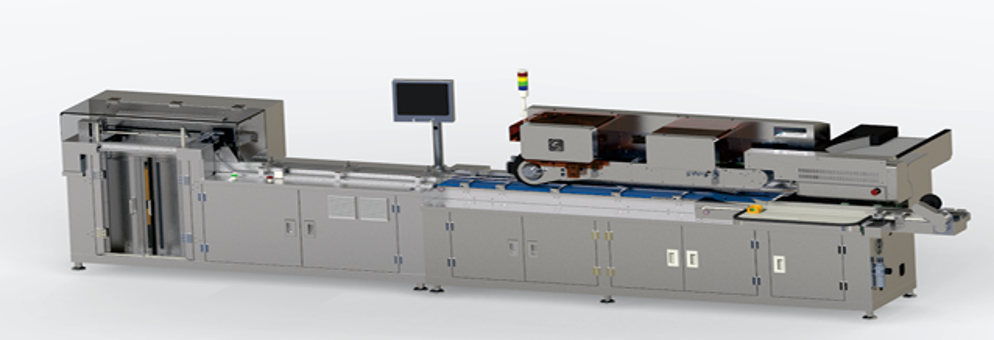

Dimensions : 4,490 mm x 1,262 mm x 1,250 mm

Speed : 1-2ml 48,000-52,000 pcs/h, 5-10ml 30,000 pcs/h, 20ml 20,000 pcs/h

Voltage : AC 220 V / 50 Hz

Power : 8.5 kW

Compressed air : 0.4-0.8 MPa

Flow rate : 30 L/min

Vacuum : > 0.02 MPa

Flow rate : > 140 L/min

Printer Image

Printing Sample